Sliding Compound Mitre Saw

Subject: Construction

Objective: Students will understand the foundational theory and applied concepts surrounding the safe use of the sliding compound mitre saw. These standards are to be cross-referenced with the OCTE Standards linked here, and confirmed with the documentation which is printed in the administration kept in the classroom itself. No student should operate any equipment without adhering to the standard operating procedures, shop safety rules, and all work, setup, maintenance, and other such shop activities must be done with the express foreknowledge and approval of the appropriate respective workshop teacher under supervision and during shop hours.

FOR OFFICIAL STANDARDS OF REFERENCE PLEASE LOOK TO THIS LINK BEFORE CONTINUING

Nothing here is intended to take precedence over the directions set out in the manufacturer’s instructions, nor those safety set out by any ministry of education, ministry of labour, educational board, or legislative body. This is purely an amalgamation of resources to support education, but is not intended to be a definitive source for safety or procedure. For your own safety, refer to your respective legislation and overarching bodies regulating standards to ensure that you are following procedures which reflect the most recent and supported bodies of research.

Intro

The sliding compound mitre saw, a very useful, important and versatile tool, is without a doubt one of the most functional and frequently used tools we have in the shop. However, it can be also one of the most dangerous tools we have if not used with care and following the proper procedures - so kindly afford it your fullest attention every time you are around it and pay attention to the safety lessons to ensure your safety. All of the tools we use here in our shop require their operators to use them in the manner they were intended, and with the appropriate supervision. If you’re ever uncertain on how to use this (or any) tool, safely stop what you’re doing and notify the instructor immediately.

Miter saws in their various forms tend to serve many functions, but their best cuts are crosscuts (cuts across the grain of the wood). More complex mitre saws like ours feature elements such as sliders, and bevel adjustments. When you’re using it, should you be cutting in a way that is not a basic 90 degree crosscut, say for instance a cut where you’re cutting on a tilt with the bevel, and an angle outside of 90 on the mitre, you’re making a compound mitre cut.

There are a number of different variations of these tools with names like “drop saw” and “chop saw,” however, when you hear someone refer to it as a chop saw they’re generally talking about a non-sliding variation which is used for metal work. Given that these can be used with a variety of materials, you should always confirm that the blade is appropriate for both the tool and the material you’re working with. Considering that the majority of woodworking projects involving these are crosscut focused, you should check to see if the blade indicates crosscut. The number of teeth is also something to consider, as the higher the number the finer the cut. Often these do need calibrating to ensure that the blade is squared to both the table and the fence. More often than not, the calibration process is done with a speed square or something similar. During that process be sure that the tool is completely disconnected from the power to reduce the likelihood of injuries.

The mitre degrees indicated along the mitre detent plate. Be sure you have the saw calibrated, adjusted to your needs, and the lock knob engaged before you begin any work.

When you have selected the material and inspected it for things like knots, cracks, foreign elements like screws/nails/staples/rocks, decide upon where you want your cut(s) to be and indicate them clearly. Remember, this tool will have blade kerf, so do not cut directly on the lines you’ve indicated; Instead, you should determine which side will be considered waste, and make your cut to that side of the line with room to adjust back to the line once you are certain it is not cutting into the final project material. Before initiating your cut be sure that you have your PPE (protective glasses and ear protection) on, that you are not wearing jewelry, that your hair and clothes are appropriately tied back if necessary, and that the material is not in direct contact with the blade. The motor on these often has substantial torque when it starts, leading to a jump or kick prior to it coming to speed, so be prepared and remain in calm and constant control of the tool.

Saw blades need to be confirmed to ensure they’re the right type for the material and type of cut, and they need to be cleaned and maintained/sharpened adequately. All such work is only to be done by the instructor or a board-approved professional.

Should you require repeated cuts of the same length, use a stop block. A good practice is to make a small 45 degree relief cut in the bottom so that you make room for sawdust - otherwise you may have a dust buildup which impedes the material from getting fully to the block and will impact your consistency. All cuts should see the blade come to a complete stop while the blade is all the way down PARTICULARLY WHEN USING A STOP BLOCK. If the blade is still spinning while you raise it, and the material has no room to shift with the movement, the loose piece touching the stop may catch the blade and become a dangerous projectile. This can be particularly challenging if the blade is not consistently cleaned, so ensure that whomever is approved to maintain the tool (teacher/board representative - NOT students) is keeping the tool maintained.

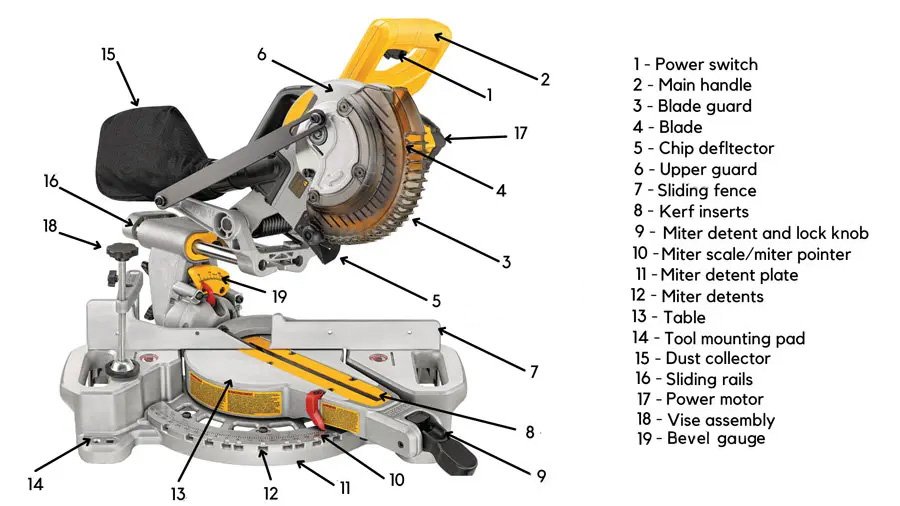

Student Safety Passport Tool Components List

For your understanding (and for your safety passport test) the main components you will be introduced to during your instruction are as follows:

This list and these images do not reflect our exact model, nor do they showcase a number of the elements we commonly use alongside it. Ours has two sliding fences and slots for the vise assembly to switch to either side; We also have table feed space on our work station to accommodate larger materials, support accessories for particularly large material, and key elements such as our pointer are located in other positions. Please refer to this as a general reference, but where differences are noticed ask the instructor to detail the tool’s safest operational procedures so that you can be as safe as is possible.

Power Switch

Main Handle

Blade Guard

Blade

Chip Deflector

Upper Guard

Sliding Fence

Kerf Inserts

Miter Detent and Lock Knob

Miter Scale and Pointer

Miter Detent Plate

Miter Detents

Table

Tool Mounting Pad

Dust Collector (Our shop uses dust collection instead)

Sliding Rails

Power Motor

Vise Assembly

Bevel Gauge

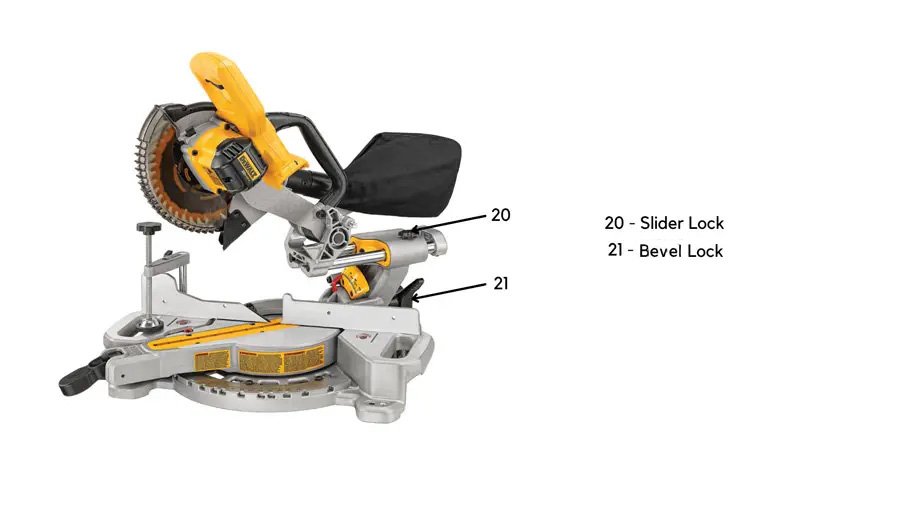

Slider Lock

Bevel Lock

While there are many other components, these are the main ones you will be expected to have a familiarity with in order to pass your student safety passport assessment demonstration. Materials should be secured properly to the table, with appropriate clamping to deliver an effective amount of pressure, in such a manner that neither the project material nor the clamps in any way impede your access to critical elements, nor cause the tool to operate in a manner it was not designed to. All personal protective equipment is a must, and you must use it at all times.

Though we often work in teams, the compound mitre saw is to be treated as a one-person tool. Any support from others during steps like setup and removing materials must be done under the direct approval of the instructor; However, only the operator and the instructor will be within the tool area when it is active - and you must always have the instructor present while operating this tool. Operating the tool while talking with others, or allowing others to be within the operational area, is not permitted. Materials may be bumped, come loose, or otherwise injure the operator or others if they are too close, so kindly remember that your attention needs to be at all times on the tool, the material, situational awareness of your environment and your safe operation within the shop. Also remember that tools with prominent spinning blade elements like this represent a hazard for not just limbs and digits, but also loose articles or hair, so do not allow anyone else near the tool while it is being operated as it can pose an extreme hazard. For full detailed understanding of your expectations, please refer to the shop rules in the classroom online workspace, the OCTE site, the board site, your course outlines, or the linked documents at the bottom of the page.

VIDEO RESOURCES

Here are some videos on mitre saws for you to learn from or review. They are here to support your understanding, but not to prepare you for your student safety passports. As these are not OCTE videos, you should refer back to your instruction in class, the OCTE-approved guidelines and instructional materials linked at the bottom of the page, or speak to your teacher if you have any questions.

A video on the fundamentals of the sliding compound mitre saw as developed by Training Hands Academy.

An interesting video on some advanced miter saw techniques. These are NOT to be applied in our shop, nor are they here to establish procedure, but I put this here to showcase the capabilities of the tool in action. Kindly remember that at all times you are expected to have PPE on when the tool is in use, specifically the protective eyewear made available to you on the wall below the first aid kit.

This video explores the elements of planes and pivot in the design of a sliding compound mitre saw in a manner that showcases its capability when applied in industry contexts. The video was made by Spencer Lewis of Insider Carpentry.

Mitre Saw ACCESSORIES

Examples of Mitre Saw accessories as demonstrated by Dan Pattison. This is not an OCTE video, please do not use or attempt anything we do not instruct in class.

Beyond adjustable material supports, dust collection alternatives, and material stops, there are many available accessories for the compound mitre saw to enable the tool to be even more versatile. Please feel free to watch this for techniques or ideas, but realize that many of the elements demonstrated do not reflect things we will explore in our classes. Do not attempt to modify our saw or use any techniques displayed without first securing express permission from your instructor.

Mitre Saw Safety

A Mitre Saw safety video developed by the Power Tool Institute. Though they do not use the same model we have in our shop, nor follow the same operational procedures, the safety concepts are universally applicable.

Unlike scroll saws, sliding compound mitre saws present an incredible risk if general safety operating procedures are not followed exactly. Nothing in this or any of the materials on this page is intended to replace the manufacturer’s instructions. This video is a bit older, and explores features and operating procedures which do not always follow what we have set out in our instruction - DO NOT USE THIS VIDEO AS AN INSTRUCTION IN PROCEDURE, REFER TO YOUR INSTRUCTOR’S DIRECTION AND LESSON DEVELOPED OCTE-APPROVED MATERIALS FOR ALL PROCEDURAL PROCESSES! Take a look at the video here exclusively to consider the safety concepts and to see demonstrations as to why we follow the procedures we do, as it showcases the risks of many mistakes in form or approach. If in doubt of anything at any time, stop working, safely shut off the machine, and ask your instructor.

Safety Rules for the Sliding Compound Mitre Saw

Unlike most of the fixed station power tools in our shop, the compound mitre saw does not use a magnetic switch. Instead the means for starting and stopping the tool is the power switch located in the main handle

Seek teacher’s permission before using the machine, ensure that the project itself has been approved, and that you have satisfied the required tool qualifications on your student safety passport. Even with safety passport approval the instructor must be present at all times when this particular tool is operated to ensure safety

Never operate any machine while under the influence of medicine, drugs, or alcohol, if you are fatigued, stressed, or otherwise emotionally/psychologically impaired. If you have any uncertainty about your ability to operate a tool or piece of equipment safely, immediately bring this to the attention of your instructor

Make sure all guards are in place and functioning as designed before starting the tool. If the tool has a lockout tag, do not use it

Use appropriate PPE (eyewear, ear protection, mask, etc.), ensure that jewelry including rings and watches are removed, and that loose/long hair, as well as articles of clothing are tied back or otherwise secured or removed

Inspect work area for cleanliness (consider debris under the table where you might step while moving the material, the table itself, and along any recesses or grooves). This machine often uses material supports which extend outside of its paint-designated work area, if this is the case you should also consider inspecting that area and notifying anyone else who may come near the supported material or accessories

Inspect the material for foreign materials, damage, or potential quality/grain issues (Consider staples in the ends, knots, cracks, or other dramatic changes in grain, rocks from the ground of a lumber yard, straps, nails, etc.). All material must have one face surfaced and one edge jointed prior to work to enable the fence and table face to be used most effectively, and proper vise clamping is suggested where appropriate

At no time are you to cut materials shorter than 6” in length using this tool. Also beware of kickback and keep yourself and others out of the potential path

Operators are always to stand ONLY on the denoted work area with their body to the left of the blade. Your right hand should operate the tool, and your left should be safely supporting the material if not otherwise appropriately secured (THIS ALSO APPLIES TO LEFT-HANDED STUDENTS)

Keep your hands out of the path of the blade even when it is off, and remember that you are not allowed to use the tool “free-hand” (where the material is not secured to the table with proper clamping). NEVER cross your hands over while operating this tool, your right hand is always to be the one activating it, and your left hand should be a minimum of 6” back from the blade or beyond the indications of the manufacturer (whichever is the longer distance)

Never force materials towards or away from the tool while the blade is in operation

Ensure the blade is sharp and in good condition, and appropriate for the material; Also, that the material is appropriate in size to accommodate the full range of motion throughout the cut without impeding movement

Do NOT start this or any tool while the blade is in contact with the material. Always bring the blade to its full operating speed before starting the cut, and the tool should come to a complete stop before lifting it again

All cuts should be properly and clearly marked with the saw locked at the appropriate angle(s), considering such things as saw kerf, path through the cut, depth and waste

Remember that the blades and materials can become incredibly hot after friction - so work carefully

Inspect and use the guard(s) appropriately every time, and also ensure that the miter detent and lock knob are set appropriately and locked in the proper place relative to the work you are doing

If the tool has an issue or any materials break, turn off machine and keep hands clear until the machine has come to a full stop and notify the instructor immediately

Aside from bevel, material, vise, miter angle adjustments, and general cleaning (with a brush or push stick only), any other adjustments to the tool are to be done by the teacher or a board-approved professional ONLY

Ensure the tool is off and the bit is completely stopped or removed entirely when removing any pieces, large or small

SEE FURTHER SAFETY DIRECTIONS IN THE LINKED SUPPORTING RESOURCES MATERIALS AT BOTTOM OF THE PAGE

Supporting Resources

Tool Specific:

OCTE Compound Mitre Saw Safety Rules

OCTE toolSAFE Compound Mitre Saw Materials

OCTE Compound Mitre Saw Lesson Plan

Broader Supporting Resources:

OCTE Health and Safety

OCTE SAFEdocs

OCTE toolSAFE

All supporting resources and much of the content are drawn directly from guidelines, standards, and materials on the OCTE pages; they are simply linked here for learner reference, and ease of instruction, however neither this page, nor the other materials represent OCTE. The other resources such as YouTube links, are included for learner refreshers.